If you’re trying to choose a blown-in insulation machine without spending a fortune, you shouldn’t need an inside connection to the HVAC industry to make a smart decision. As neighbors who’ve spent years working in homes throughout the community—and shoulder-to-shoulder with the crews who run these machines day in and day out—we’ve learned exactly which models stay reliable, which rental programs are worth the drive, and which “too cheap to be true” options usually cause more frustration than savings.

From our experience in local attics and crawl spaces, the right blown-in machine doesn’t just make the job easier. It helps you get even coverage, hit the R-value your home needs, and avoid the clogs and slowdowns that can turn a simple upgrade into an all-day project. Think of this guide as the honest, neighbor-to-neighbor version of what contractors share among themselves—clear, practical insights to help you choose a machine with confidence.

TL;DR Quick Answers

Blown-in insulation machine

A blown-in insulation machine is a specialized blower that feeds loose-fill insulation—like cellulose or fiberglass—through a hose to evenly cover attics, walls, or hard-to-reach areas. From our hands-on experience working with installers and homeowners, the key is choosing a machine with consistent airflow and a reliable agitator. Those two features make the biggest difference in how smoothly your project goes and how well the insulation settles for long-term performance.

Top 5 Things to Know Before You Rent or Buy

- Consistent airflow and strong agitation matter more than raw horsepower.

From what we’ve seen in local homes, machines that keep insulation moving smoothly deliver better coverage than those that simply boast high power numbers.

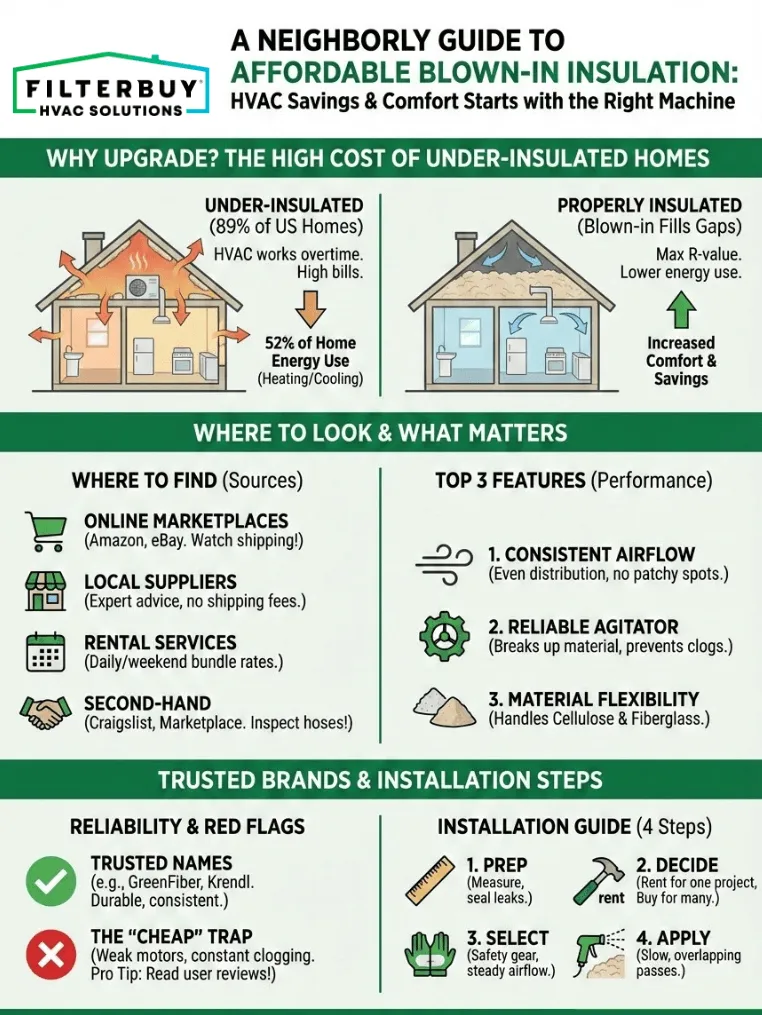

- Most homes in our area are under-insulated.

Whether we’re inspecting older builds or newer starter homes, we regularly find insulation levels far below modern recommendations—making blown-in upgrades one of the most effective comfort improvements a homeowner can make.

- Heating and cooling are your biggest energy expenses.

Insulation directly affects how hard your HVAC system has to work. Properly installed blown-in insulation protects your comfort and your budget through every season.

- Reliable machines prevent clogs, uneven coverage, and wasted time.

A dependable machine helps you avoid the frustration of restarting, unclogging hoses, or dealing with patchy insulation that has to be redone later.

- A little prep goes a long way.

Measuring your current insulation levels, checking for air leaks, and sealing problem areas before blowing in new material dramatically improves results—something we’ve seen over and over in local homes.

Exploring Online Marketplaces

If you’re trying to keep costs down, starting your search online can be a smart move. Sites like Amazon, eBay, and other large marketplaces usually offer a wide mix of blown-in insulation machines—from entry-level options to sturdier contractor-grade models. What we often tell neighbors is this: don’t just look at the price tag. Pay attention to reviews from people who’ve actually used the machine in real homes, because those real-world insights often tell you more than any product description.

And one detail homeowners sometimes overlook is shipping. Depending on where you live, delivery fees can turn an affordable machine into a pricier one. Some sellers offer free shipping, which saves quite a bit, especially on heavier equipment. Just take a moment to compare sellers side by side and check for any hidden add-ons before you commit. Most platforms offer customer support if you need clarification—use it. A few minutes of digging usually leads to the best value.

Rental Services for Short-Term Needs

If you’re only planning to tackle one insulation project—or you simply don’t see yourself using the machine often—renting can be the most budget-friendly route. Around our community, we see plenty of homeowners and small contractors choosing rentals because they offer flexible timing: a single day, a weekend, or even a week if you need a little extra breathing room.

Rental prices vary more than people expect. Some places charge by the hour, while others offer daily or weekend bundles that can save money, especially if you’re working at a steady pace. Just be sure to ask about deposits, cleaning fees, or insurance requirements, so you have a clear picture of the total cost. With the right rental program, you get a solid machine without the long-term expense.

Checking Out Local Suppliers

Don’t overlook your local hardware stores and building supply shops—many of them carry blown-in insulation machines designed for specific materials like cellulose or fiberglass. And there’s a real advantage here: you can talk to someone face-to-face who understands the homes in our area. That local insight helps ensure you get the right match between machine, insulation type, and the layout of your home.

Buying or renting locally also supports businesses in our community, and in our experience, that often comes with better customer service and more personal after-care. Some stores even run seasonal promotions that can save you money. Plus, staying local can cut down on pickup and return time, making the entire project a lot more convenient.

Considering Second-Hand Options

For homeowners trying to stretch their budget, a well-maintained second-hand machine can be a surprisingly smart choice. You can save a significant amount if you know what to look for. We always recommend checking the condition closely: look for signs of wear on the hopper, hoses, and wheels, and—if possible—ask the previous owner how often it was used and how it was stored.

Platforms like Craigslist, eBay, Facebook Marketplace, and even local auctions regularly have used machines available. Rental companies sometimes sell older—but still reliable—units when upgrading their fleet. While a new machine guarantees pristine condition, many second-hand models perform just as well with the right care. A thoughtful inspection often leads to a dependable buy without the higher upfront cost.

Comparing Brands and Models for Cost Efficiency

Over the years, we’ve worked with most of the major brands in homes throughout our community, and a few names tend to hold up better than others. GreenFiber and Krendl, for example, have built a reputation for durability—something that matters when you’re trying to avoid clogs and downtime in the middle of a project.

Still, the “best” machine isn’t always the one with the highest horsepower. What really matters is how well the machine performs for your specific project: capacity, airflow consistency, material compatibility, and ease of use. A model with a slightly higher upfront cost may actually save you time, energy, and frustration in the long run. Customer reviews remain one of the most helpful tools here—they reveal how machines behave in real attics, not just in product manuals.

If you balance brand reliability, machine performance, and long-term value, you can find a great option without overspending.

“In all the years we’ve been helping homeowners upgrade insulation here in our community, one thing has stayed consistent: the machines that perform best are the ones with steady airflow and a strong agitator. When either of those is weak, you’ll notice it right away—clogged hoses, patchy coverage, and a project that takes twice as long as it should. The right machine makes the whole job smoother, cleaner, and far more efficient.”

Essential Resources for Choosing the Right Blown-In Insulation Machine

1. Greenfiber: How to Choose the Right Blower for Cellulose Insulation

A practical guide that breaks down airflow, hopper design, and machine power so you can match the right blower to your insulation type and project size.

2. IDI Insulation: Best Blown-In Insulation Machines Compared

A side-by-side comparison of entry-level, mid-range, and high-output machines — including production rates and cost expectations — to help you narrow your options quickly.

3. PDQuipment: How to Select Blower Equipment for Contractors

Real-world advice on choosing machines that hold up under jobsite conditions, evaluating warranties, and understanding long-term maintenance needs.

URL: https://www.pdquipment.com/how-to-choose-the-right-insulation-blowing-machine-for-contractors/

4. InsulationMachines.net: Step-By-Step Guide to Using a Blower

A clear walkthrough of how blown-in insulation machines actually perform in the field, including setup, operation, and common troubleshooting steps.

URL: https://insulationmachines.net/tips-and-tricks/how-to-use-a-blown-insulation-machine/

5. Angi: Renting a Blown-In Insulation Machine

A straightforward resource explaining how blown-in insulation machine rentals work, what to check before renting, and how to avoid common equipment mismatches.

URL: https://www.angi.com/articles/cost-to-rent-blown-insulation-machine.htm

6. Bob Vila: Complete Guide to Blown-In Insulation Materials & Costs

A homeowner-friendly overview of blown-in insulation types, project costs, pros and cons, and where blown-in makes the biggest impact.

URL: https://www.bobvila.com/articles/blown-in-insulation/

7. Fine Homebuilding: Choosing & Installing Blown-In Insulation

Contractor-level guidance on assessing conditions, sealing air leaks, and ensuring proper installation quality before using a blower.

Supporting Statistics

1. Most Homes in the U.S. Are Under-Insulated

According to NAIMA, 89% of single-family homes don’t have enough insulation — a number that matches exactly what we’ve seen in attics across our own community. Even when an attic “looks full,” it often falls well below today’s recommended R-values.

Blown-in insulation is one of the fastest ways to close those gaps and create a more even, protective layer across the entire attic floor.

Source: insulationinstitute.org

2. Heating & Cooling Use About 52% of the Average Home’s Energy

The U.S. Energy Information Administration reports that more than half of a home’s total energy use goes directly to heating and cooling. That means anything that reduces the strain on your HVAC system can immediately impact your monthly bills.

When we upgrade attic insulation using a properly performing blower, homeowners often feel the difference within days — more stable temperatures and less cycling from their AC or furnace.

Source: eia.gov

3. Better Sealing + Proper Insulation = Around 15% Energy Savings

ENERGY STAR estimates that improving insulation and sealing air leaks can save homeowners about 15% on heating and cooling costs.

In many older homes in our area, we’ve seen blown-in insulation outperform even that number, simply because it reaches irregular or hard-to-access spaces that batt insulation often misses

Source: energystar.gov

These numbers confirm what we observe in local homes every day: the right blown-in insulation machine doesn’t just speed up the installation — it leads to real improvements in comfort, efficiency, and monthly energy use.

Final Thoughts & Our Local Perspective

Upgrading your home’s insulation isn’t just about blowing in more material—it’s about using the right machine so the insulation settles evenly, performs well through every season, and delivers the comfort your home has been missing. After working in attics across our community for years, we’ve seen how much of a difference the right blower can make in both the installation process and the long-term results.

What Homeowners Should Know

Most homes in our area simply don’t have enough insulation, and blown-in material is one of the quickest, most effective ways to fix that. Since heating and cooling make up the biggest share of your energy use, even a modest improvement in insulation can translate into noticeable savings.

And here’s something many neighbors don’t realize: the machine you use plays a major role in how well the insulation performs. Coverage, comfort, and long-term efficiency all improve when the job is done with a reliable blower.

What We’ve Seen in Local Homes

From years of fieldwork, a few patterns show up again and again:

- Consistency matters more than horsepower. Machines with steady airflow and strong agitation deliver the smoothest, most even coverage.

- Ultra-cheap blowers often cost more in the long run. We’ve seen clogs, jams, and uneven layers that lead to extra time—and sometimes redo work.

- Reliable machines create real, immediate comfort improvements. Homeowners often notice fewer drafts, more stable temperatures, and quieter HVAC operation within days.

Our Take

If your goal is better comfort and lower energy bills, choose a machine that’s known for dependable airflow and consistent distribution. A smooth-running blower doesn’t just make the job easier—it helps your insulation perform better than the specs on the bag.

Next Steps: A Neighborly Guide to Moving Forward

- Check Your Insulation Needs

- Measure your attic’s insulation depth.

- Look for low spots, settling, or drafty areas.

- Compare what you have to ENERGY STAR recommendations for your region.

- Decide Whether to Rent or Buy

- Rent if you’re handling a single project.

- Buy if you plan to improve multiple areas over time.

- Compare machines by airflow strength, agitator design, and hopper size.

- Pick a Reliable Machine

- Choose models known for steady, consistent airflow.

- Avoid machines with a reputation for clogs or uneven distribution.

- Check reputable reviews and ask local pros if you’re unsure.

- Prep the Space

- Choose your insulation type (cellulose or fiberglass).

- Seal air leaks and repair any attic gaps.

- Gather basic safety gear: mask, gloves, and goggles.

- Set Up Safely

- Place the machine on a stable, clear surface.

- Double-check hose connections.

- Start with moderate airflow and adjust as you go.

- Apply Even Coverage

- Work slowly with overlapping passes.

- Pay extra attention to low or irregular areas.

- Check depth regularly to stay consistent.

- Verify the Results

- Measure final insulation depth across multiple points.

- Look for thin spots or inconsistencies.

- Keep an eye on comfort and energy bills—many homeowners see improvements quickly.

FAQ: Neighbor-to-Neighbor Answers

Q: What does a blown-in insulation machine actually do?

A: It breaks up loose-fill insulation and sends it through a hose so you can spread it evenly across the attic. Machines with steady airflow provide the smoothest, most uniform coverage—especially in older homes with tricky layouts.

Q: Should I rent or buy?

A:

- Rent if it’s a one-time project.

- Buy if you’re upgrading several areas or helping others.

Q: Which features matter most?

A: Consistent airflow and a strong agitator. These two features prevent clogs and help you reach the recommended depth with less effort.

Q: Can most machines handle both cellulose and fiberglass?

A: Yes. Most modern blowers do well with both materials, though cellulose tends to feed a bit more smoothly.

Q: How long does the job take?

A: For a standard attic, plan on 1–3 hours. Machines with more stable airflow typically finish faster and produce a more even layer.

Skip the Search for an Affordable Blown-In Insulation Machine—Let Our Local Pros Handle It

Now that you know where to find the right blown-in insulation machine, why not let our experienced crew do the heavy lifting instead? Contact Filterbuy HVAC Solutions today for a free insulation assessment and get the even, professional-grade coverage your home deserves—no equipment hunting required.