A new HVAC system for a 2,000 square foot home typically runs between $10,000 and $20,000, with most homeowners landing around $14,000 for a complete heating and cooling setup. But here’s what those generic estimates don’t tell you: after installing systems in homes across our community for years, we’ve learned that the biggest cost driver isn’t usually the equipment itself—it’s whether the contractor takes shortcuts that cost you thousands down the road.

We’ve walked into too many homes where a previous installer undersized the system to win the bid, leaving homeowners with a unit that runs constantly, drives up energy bills, and wears out years early. Proper load calculations, ductwork assessment, and right-sizing your system matter far more than chasing the lowest quote.

This guide shares what we’ve learned from real installations in real homes—including the factors that push costs toward $20,000, where you can reasonably save money without sacrificing performance, and the red flags that separate trustworthy contractors from those cutting corners. Your HVAC system is a decade-long investment in your family’s comfort, and we want you to walk into this decision with the same knowledge we’d give our own neighbors.

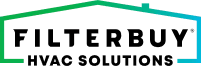

TL;DR Quick Answers

How much does a new HVAC system cost for a 2,000 sq ft house?

Short answer: $10,000 to $20,000, with most homeowners paying around $14,000.

Cost breakdown by system type:

- Central AC + gas furnace: $8,000-$14,000

- Heat pump system: $10,000-$16,000

- Dual fuel (heat pump + furnace backup): $12,000-$18,000

What drives costs higher:

- Ductwork replacement adds $2,000-$6,000

- High-efficiency equipment adds $2,000-$4,000

- Complex installation or access issues

- Multi-zone configurations

What keeps costs lower:

- Sound existing ductwork

- Standard efficiency equipment

- Straightforward replacement

- Off-season installation (spring or fall)

What we tell homeowners: The quote that matters isn’t the lowest number—it’s the one backed by proper load calculations, licensed installation, and warranty terms that protect your investment for the next 15-20 years.

Available savings to factor in:

- Federal tax credits: up to $600 (AC) or $2,000 (heat pumps)

- Utility rebates: vary by location and efficiency rating

- Check energystar.gov/rebate-finder before purchasing

Top Takeaways

- Budget $10,000 to $20,000 for a complete system. Most homeowners pay around $14,000. Final cost depends on system type, efficiency rating, ductwork condition, and installation complexity.

- Proper sizing beats premium brand names. A correctly sized mid-tier system outperforms an expensive unit at the wrong capacity. Demand Manual J load calculations—not square-footage guesses.

- The lowest bid usually costs more in the long term. Undersized equipment and rushed installations create years of problems. Evaluate sizing methodology and warranty terms, not just price.

- Capture available incentives before you buy. Federal tax credits reach up to $2,000 for heat pumps and $600 for central AC. Check energystar.gov/rebate-finder for your zip code.

- Verify credentials before scheduling estimates. Confirm state licensing, current insurance, and BBB history. Five minutes of research protects a 15-20 year investment.

What Determines HVAC System Cost for a 2,000 Sq Ft Home

The price gap between an $8,000 installation and an $18,000 one comes down to five main factors: system type, efficiency rating, existing ductwork condition, installation complexity, and the contractor you choose.

System type creates the first major price split. A standard central air conditioner paired with a gas furnace typically costs $8,000 to $14,000 installed. Heat pump systems, which handle both heating and cooling in a single unit, range from $10,000 to $16,000 but often deliver lower operating costs in moderate climates. Dual fuel systems combining a heat pump with a gas furnace backup run $12,000 to $18,000—a premium option we often recommend for homeowners wanting maximum efficiency without sacrificing heating power during extreme cold snaps.

Efficiency ratings directly impact both upfront cost and long-term savings. Higher SEER2 ratings mean better cooling efficiency, with current federal minimums requiring at least 14.3 SEER2 in southern regions. Upgrading from a basic 14 SEER2 system to a 20 SEER2 unit adds $2,000 to $4,000 upfront but can reduce cooling costs by 30% or more annually. In our experience, most homeowners in hot climates recoup that investment within five to seven years through lower utility bills.

System Sizing: Where Many Installations Go Wrong

A 2,000 square foot home generally needs 3 to 4 tons of cooling capacity and 60,000 to 100,000 BTUs of heating power. But square footage alone doesn’t tell the whole story—and this is where we’ve seen the most expensive mistakes happen.

Proper sizing requires a Manual J load calculation that accounts for insulation quality, window placement, ceiling height, local climate, and even which direction your home faces. We’ve walked into homes where contractors sized systems purely on square footage, leaving families with units that short-cycle, create uneven temperatures, and fail years before they should.

An oversized system cools quickly but shuts off before removing humidity, leaving your home clammy and uncomfortable. An undersized system runs constantly, driving up energy bills and wearing out components prematurely. Both scenarios cost homeowners thousands in wasted energy and early replacements. Any contractor unwilling to perform load calculations before quoting should raise immediate red flags.

Ductwork: The Hidden Cost Many Homeowners Miss

Your ductwork condition can add $2,000 to $6,000 to an HVAC replacement—or nothing at all if your existing ducts are sound. This is one area where an honest assessment upfront saves major headaches later.

Signs your ductwork may need attention include visible damage or disconnections, rooms that never reach comfortable temperatures, excessive dust throughout your home, or ducts older than 15 years. Leaky ductwork can waste 20% to 30% of conditioned air before it ever reaches your living spaces, meaning even a brand-new high-efficiency system underperforms from day one.

We evaluate ductwork during every consultation because installing premium equipment on failing ducts is like putting racing tires on a car with a broken axle. Sometimes sealing and insulating existing ducts solves the problem for $500 to $1,500. Other times, replacement makes more sense. Either way, you deserve to know before signing any contract.

Breaking Down Installation Labor Costs

Labor typically accounts for $1,500 to $4,000 of your total project cost, varying based on regional rates, installation complexity, and contractor experience.

Straightforward replacements where new equipment connects to existing ductwork and electrical take less time and cost less. Installations requiring electrical panel upgrades, new refrigerant lines, thermostat relocation, or attic and crawlspace work add hours and dollars. Multi-story homes and complex layouts can increase labor costs by 20% to 30% compared to single-story ranch-style homes with easy equipment access.

Permit fees add another $100 to $500, depending on your municipality. Legitimate contractors pull permits and schedule inspections—it protects you legally and ensures the work meets code. Any contractor suggesting you skip permits to save money is putting your investment and potentially your family’s safety at risk.

When Repair Makes More Sense Than Replacement

Not every HVAC problem requires a full system replacement. Understanding when repair still makes sense can save you thousands.

Consider repair if your system is under 10 years old, the repair costs less than half the cost of replacement, and you haven’t experienced repeated breakdowns. A failed capacitor, refrigerant recharge, or blower motor replacement typically runs $150 to $600—well worth it for a system with years of life remaining.

Replacement becomes the smarter choice when your system exceeds 15 years, uses R-22 refrigerant (now phased out and expensive), requires repairs exceeding 50% of replacement cost, or consistently fails to maintain comfortable temperatures despite repairs. We’ve also seen cases where a 12-year-old system technically still runs but operates so inefficiently that replacement pays for itself within a few years through energy savings alone.

How to Avoid Overpaying for Your New System

Getting fair pricing starts with understanding what legitimate HVAC installation includes and recognizing warning signs of inflated quotes or corner-cutting.

Always obtain at least three written estimates from licensed, insured contractors. Each estimate should itemize equipment model numbers, labor costs, permit fees, and warranty terms. Vague line items like “materials” or “miscellaneous fees” without explanation deserve clarification. Ask every contractor about their load calculation process—if they quote based on square footage alone, move on.

Be cautious of bids significantly lower than those of competitors. That $6,000 quote undercutting everyone else often signals cheaper equipment, inexperienced installers, or plans to add charges mid-project. We’ve helped homeowners recover from installations where low-bid contractors used incorrect refrigerant line sizes, skipped ductwork sealing, or installed undersized systems that never performed properly.

Timing your installation strategically can also reduce costs. Spring and fall typically offer better pricing and scheduling flexibility since contractors aren’t slammed with emergency summer cooling or winter heating calls. Planning gives you negotiating leverage and ensures you’re not making rushed decisions during a breakdown.

What Your Investment Should Include

A quality HVAC installation for your 2,000 square foot home should include more than just equipment delivery and hookup. Here’s what to expect from contractors who stand behind their work.

Comprehensive service includes a thorough load calculation, equipment recommendations matched to your home’s specific needs, professional installation with proper refrigerant charging, ductwork inspection and sealing as needed, thermostat setup and homeowner education, permit acquisition and inspection scheduling, and clear warranty documentation covering both equipment and labor.

Equipment warranties from major manufacturers typically cover parts for 5 to 10 years, with some offering extended coverage when registered within a specific timeframe. Labor warranties vary by contractor—we believe homeowners deserve at least one year of labor coverage, and reputable companies often provide more.

Your contractor should walk you through system operation, filter replacement schedules, and maintenance requirements before considering the job complete. This isn’t just good service—proper homeowner education extends system life and prevents avoidable service calls.

Making the Right Decision for Your Home

Replacing your HVAC system represents one of the larger investments you’ll make in your home, but it’s also one that directly impacts your family’s daily comfort and your monthly expenses for the next 15 to 20 years.

The right system at the right price exists for your situation. It requires working with contractors who take time to understand your home, explain your options honestly, and stand behind their installations. Rushing this decision to escape summer heat or winter cold often leads to regret—and to service calls from contractors like us trying to correct preventable problems.

We encourage every homeowner to ask questions, request detailed estimates, and trust their instincts about the contractors they meet. Your comfort and your investment deserve nothing less.

“After years of installing HVAC systems in homes just like yours, we’ve learned that the difference between a system that lasts 10 years and one that lasts 20 often comes down to what happens during installation—not what’s printed on the equipment box.”

— Filterbuy HVAC Solutions

Essential Resources for Making a Smart HVAC Investment

After years of serving homeowners in our community, we’ve learned that the best-prepared customers make the best decisions. These seven resources—the same ones we consult and recommend—give you access to industry standards, government programs, and consumer protection tools that level the playing field when you’re facing a major HVAC purchase.

We’re sharing these because we believe informed homeowners deserve more than a sales pitch. When you understand how proper sizing works, what incentives you qualify for, and how to verify a contractor’s credentials, you’re equipped to ask the right questions and recognize the difference between a fair quote and one that’s missing critical details.

ACCA Manual J: The Sizing Standard Every Contractor Should Follow

We’ve seen too many homeowners stuck with systems that never quite keep their homes comfortable—and in almost every case, the problem traces back to improper sizing. The Air Conditioning Contractors of America developed Manual J as the industry-recognized method for calculating exactly how much heating and cooling capacity your specific home requires.

This isn’t about square footage alone. A proper Manual J calculation accounts for your insulation levels, window placement, ceiling heights, local climate, and even which direction your home faces. When a contractor skips this step and quotes based on a quick square-footage estimate, they’re guessing—and that guess can saddle you with an oversized system that short-cycles and never removes humidity, or an undersized unit that runs constantly and wears out years early.

Before accepting any quote, ask whether the contractor performs Manual J load calculations. If they hesitate or dismiss the question, consider it a red flag.

Source: Air Conditioning Contractors of America (ACCA)

URL: https://www.acca.org/standards/technical-manuals/manual-j

ENERGY STAR Rebate Finder: Don’t Leave Money on the Table

One of the most common conversations we have with homeowners happens after they’ve already purchased a system—when they discover rebates and tax credits they didn’t know existed. Federal programs currently allow you to recover up to $3,200 annually on qualifying energy-efficient upgrades, with heat pumps eligible for up to $2,000 and central air conditioners up to $600.

Beyond federal incentives, your local utility company may offer additional rebates that can significantly reduce your out-of-pocket costs. These programs change regularly, and eligibility depends on your specific location and the efficiency ratings of the equipment you choose.

We encourage every homeowner to check this database before finalizing any purchase. Five minutes of research can translate into hundreds or even thousands of dollars back in your pocket.

Source: U.S. Environmental Protection Agency and U.S. Department of Energy

URL: https://www.energystar.gov/rebate-finder

DOE Efficiency Standards: Understanding What Your Region Requires

The Department of Energy sets minimum efficiency requirements that vary by geographic region—and these standards directly affect what equipment can legally be installed in your home, what qualifies for tax credits, and how much you’ll pay in operating costs over the life of your system.

If you live in a Southern or Southwestern state, you’re subject to higher minimum SEER2 ratings than homeowners in Northern regions. Equipment that met standards a few years ago may no longer be compliant, and systems that barely meet today’s minimums won’t qualify for most incentive programs.

Understanding these requirements before you start collecting quotes helps you evaluate whether a contractor is recommending equipment that just clears the bar or genuinely serves your long-term interests. It also prevents unpleasant surprises when you file for tax credits and discover your system doesn’t qualify.

Source: U.S. Department of Energy, Federal Energy Management Program

URL: https://www.energy.gov/femp/purchasing-energy-efficient-residential-central-air-conditioners

EPA Indoor Air Quality Guide: Your HVAC System Does More Than Heat and Cool

When families tell us about persistent allergy symptoms, stuffy rooms, or humidity problems that never quite resolve, the conversation often leads to their HVAC system. Your heating and cooling equipment is the primary mechanism for filtering airborne particles, controlling humidity, and circulating fresh air throughout your home—functions that directly impact your family’s health and comfort.

The EPA’s indoor air quality resources help you understand how ventilation rates, filter ratings, and humidity control work together to create healthier indoor environments. Indoor air can contain two to five times more pollutants than outdoor air, and the system you choose—along with how it’s maintained—plays a significant role in what your family breathes every day.

We recommend reviewing this guide before your consultation so you can ask informed questions about filtration options, humidity control features, and ventilation capabilities that go beyond basic heating and cooling.

Source: U.S. Environmental Protection Agency

URL: https://www.epa.gov/indoor-air-quality-iaq

BBB Contractor Directory: Look Beyond the Five-Star Google Reviews

Here’s something we tell every homeowner: the reviews you see on a contractor’s website or Google listing don’t always tell the complete story. The Better Business Bureau received more than 6,000 complaints about heating and cooling contractors last year, and many of those businesses still display glowing testimonials elsewhere online.

The BBB directory shows you complaint history, how companies responded to problems, whether disputes were resolved, and how long a business has been operating. Patterns matter more than individual reviews—a contractor with dozens of complaints about billing surprises or incomplete installations reveals more than a handful of curated five-star ratings.

We believe reputable contractors welcome this scrutiny. Checking BBB profiles takes minutes and can save you from becoming another complaint statistic.

Source: Better Business Bureau

URL: https://www.bbb.org/near-me/air-conditioning-contractor

NerdWallet HVAC Financing Guide: Know Your Options Before the Sales Pitch

Contractor financing can be convenient, but it isn’t always your best option. Interest rates on HVAC loans range from 6% to 36%, depending on your credit score, the loan type, and the lender. The difference between a 10% rate and a 20% rate on a $14,000 system adds up to thousands of dollars over the repayment period.

This guide compares personal loans, home equity products, FHA Title I loans (which allow up to $25,000 for home improvements), and promotional 0% credit card offers. Understanding these options before you sit down with a contractor prevents pressure decisions and ensures you’re not accepting high-interest dealer financing simply because it’s presented as the only path forward.

We’ve seen homeowners save significantly by arranging their own financing before the consultation. It also sends a clear signal that you’ve done your homework, which tends to keep quotes honest and recommendations focused on your actual needs.

Source: NerdWallet

URL: https://www.nerdwallet.com/home-ownership/home-improvement/best/hvac-financing

Supporting Statistics: What the Data Confirms About HVAC Performance

After years of installing and servicing HVAC systems in homes throughout our community, we’ve developed strong opinions about what works. These statistics from federal agencies and industry organizations validate what we see daily—and explain why we emphasize proper sizing, air quality, and genuine efficiency over quick-fix solutions.

Indoor Air Quality Affects Your Family More Than You Realize

We hear it constantly: families call about temperature problems and discover their real issue is air quality. Stuffy rooms. Persistent allergies. Humidity that never feels right.

What the EPA confirms:

- Indoor air contains pollutant concentrations two to five times higher than outdoor air

- In some cases, indoor pollution reaches 100 times the outdoor levels

- Most Americans spend approximately 90 percent of their time indoors

What we see in local homes:

- Undersized return ducts restricting airflow

- Filters unchanged for months

- The equipment is running without proper ventilation integration

The cheapest system that technically heats and cools may leave your family breathing air that’s measurably worse than what’s outside. This is why we discuss filtration, humidity control, and ventilation during every consultation—even when homeowners initially just want to talk price.

Source: U.S. Environmental Protection Agency — Introduction to Indoor Air Quality

URL: https://www.epa.gov/indoor-air-quality-iaq/introduction-indoor-air-quality

Central HVAC Is Essential Infrastructure, Not an Optional Upgrade

When homeowners hesitate about investing in quality equipment, we understand. These systems cost as much as a used car. But the data reframes this decision.

What the Energy Information Administration reports:

- 76 million American homes (64% of households) use central air conditioning

- 13 million additional homes (11%) rely on heat pumps for primary heating and cooling

- Combined, three-quarters of U.S. households depend on central HVAC systems

What this means for your purchase:

- Your HVAC system will run thousands of hours over 15-20 years

- It affects comfort, energy bills, and health every single day

- This is infrastructure that makes your home livable—not an appliance to forget about

Homeowners who approach this as essential infrastructure make better decisions. They ask more questions, evaluate contractors carefully, and end up with systems that actually deliver on comfort and efficiency promises.

Source: U.S. Energy Information Administration — Efficiency Requirements for Residential Central AC and Heat Pumps

URL: https://www.eia.gov/todayinenergy/detail.php?id=40232

New Efficiency Ratings Reflect How Systems Actually Perform

Confused about SEER versus SEER2? Here’s what changed: old testing methods didn’t account for real-world installation conditions. Laboratory tests with minimal airflow resistance don’t reflect actual ductwork, registers, and the variables affecting daily operation.

What the updated SEER2 standards changed:

- External static pressure increased five times compared to the previous testing

- New protocols simulate real ductwork and real home conditions

- Equipment meeting current minimums performs approximately 7% more efficiently

What we’ve observed across installations:

- Properly rated SEER2 equipment matched to accurate load calculations delivers expected performance

- Systems sized under old methods often fall short once connected to actual ductwork

- Many families report their previous system “never really kept the house comfortable.”

When we recommend specific efficiency ratings, we’re applying data that reflects conditions like yours—not laboratory conditions designed to make specifications look impressive.

Source: Air-Conditioning, Heating, and Refrigeration Institute — 2023 Energy Efficiency Standards

URL: https://www.ahrinet.org/2023-energy-efficiency-standards

Why Data Matters Alongside Experience

We could fill pages with installation stories. But anecdotes only go so far for a decision this significant.

These statistics come from sources with no financial stake in your choice:

- EPA tracks indoor air quality across millions of homes

- EIA surveys confirm patterns nationwide

- AHRI sets testing standards based on real-world performance data

When research aligns with our firsthand observations, we gain confidence that our recommendations serve your interests—not just our bottom line.

Informed homeowners make better partners. Understanding why these considerations matter lets our conversations focus on finding the right solution rather than convincing you that these factors exist.

Final Thoughts: What We’ve Learned About HVAC Investments

After serving homeowners in our community for years, we’ve seen the full spectrum of HVAC purchases. Installations that deliver reliable comfort for two decades. Systems that create headaches from day one.

The difference rarely comes down to brand names or flashy features. It comes down to whether the fundamentals were done right.

What the Numbers Tell Us

The data throughout this guide points to a consistent theme:

- Costs are significant but predictable. Most homeowners pay $10,000 to $20,000 for a complete system in a 2,000-square-foot home. The typical investment lands around $14,000.

- Indoor air quality matters more than most realize. Indoor pollutant levels run two to five times higher than outdoor air. Your system’s filtration and ventilation directly impact family health.

- Efficiency standards have real-world implications. Updated SEER2 testing reflects actual installed performance—not laboratory conditions.

- Resources exist to protect you. Federal tax credits, state licensing boards, BBB records, and industry sizing standards give you the same information professionals use.

What Experience Has Taught Us

Here’s our honest perspective after installing systems in homes just like yours:

The lowest bid almost always costs more in the long run.

We’ve lost count of service calls to homes where previous contractors undersized equipment, skipped load calculations, or rushed installation to hit a price point. Those families didn’t save money. They paid twice—once for the original installation that never worked properly, and again to fix problems that should never have existed.

Proper sizing isn’t optional. It’s everything.

- A top-rated system installed at the wrong capacity will disappoint you for its entire lifespan.

- An appropriately sized mid-tier system with correct airflow will outperform it every time.

- We’ve seen this pattern hundreds of times—it never changes

Contractors who resist questions aren’t worth your trust.

When we explain Manual J calculations, discuss efficiency trade-offs, or walk through warranty details, we’re protecting your investment. Any contractor who dismisses these conversations is telling you something about how they’ll handle problems after your check clears.

Your HVAC system is a 15-20 year relationship.

The equipment you choose today will affect:

- Your sleep quality

- Your energy bills

- Your allergy symptoms

- Your home’s resale value

Treating this purchase as a commodity—chasing the lowest quote—ignores everything that determines satisfaction.

Our Recommendation

Before anyone arrives with a quote:

- Use the resources we’ve shared to understand proper sizing

- Check available tax credits and rebates for your zip code

- Verify contractor credentials through your state licensing board

- Compare financing options independently

When collecting estimates:

- Get at least three quotes from licensed contractors

- Confirmthat each performs Manual J load calculations

- Ask them to explain their sizing methodology

- Notice who answers questions thoroughly versus who pressures for quick decisions

Remember: The goal isn’t finding the cheapest system. It’s finding the right system installed correctly by people who stand behind their work.

The Bottom Line

A new HVAC system represents one of your larger investments as a homeowner. The difference between 20 years of reliable comfort and ongoing frustration comes down to five questions answered before installation day:

- Was the system properly sized using industry-standard calculations?

- Does equipment efficiency match your climate and usage patterns?

- Is your contractor licensed, insured, and accountable?

- Will the installation meet code requirements and manufacturer specifications?

- Do warranty terms protect both equipment and labor?

Get these fundamentals right, and brand or model matters far less than marketing suggests. Get them wrong, and no premium equipment compensates for underlying problems.

Your family deserves a home that’s comfortable, healthy, and efficient. This guide gives you the foundation to make that happen—with confidence.

Next Steps: Your Action Plan for a Successful HVAC Investment

You’ve done the research. Now it’s time to put that knowledge to work. These steps guide you from preparation through installation—helping you avoid common pitfalls and decide with confidence.

Step 1: Assess Your Current Situation

Before contacting any contractor, answer these questions:

- How old is your current system? (Over 15 years typically warrants replacement consideration)

- Are you experiencing uneven temperatures, humidity issues, or rising energy bills?

- Have repair costs exceeded $500 in the past year?

- Does your system use R-22 refrigerant? (Phased out and increasingly expensive)

Document specific issues:

- Which rooms never reach comfortable temperatures

- Unusual noises or odors

- How often does the system cycle on and off

- Recent repair history

This information helps contractors provide accurate assessments—and helps you evaluate whether their recommendations address your actual concerns.

Step 2: Research Available Incentives

Check these resources before collecting quotes:

- ENERGY STAR Rebate Finder (energystar.gov/rebate-finder) — Federal tax credits and local utility rebates for your zip code

- Your utility provider’s website — Additional rebates and free energy audit programs

- State energy office — State-level incentives and income-qualified programs

Know your potential savings:

- Up to $600 tax credit for qualifying central air conditioners

- Up to $2,000 tax credit for qualifying heat pumps

- Utility rebates vary by equipment type and efficiency rating

Factor these savings into your budget before evaluating quotes.

Step 3: Verify Contractor Credentials

For each contractor you consider, confirm:

- Active state license through your licensing board’s verification portal

- Current liability insurance and workers’ compensation coverage

- BBB rating and complaint history

- Reviews across multiple platforms

- Authorized dealer status for recommended equipment

Red flags to avoid:

- Unable to provide license number

- No physical business address

- Pressure to decide immediately

- Cash-only or no-contract offers

- Patterns of billing surprises in reviews

Step 4: Schedule Consultations

Contact at least three licensed contractors. Request:

- In-home assessment (not phone-based quotes)

- Manual J load calculation

- Written estimate itemizing equipment, labor, permits, and warranty

Ask each contractor:

- What size system does my home require, and how did you calculate that?

- Which efficiency rating do you recommend and why?

- What does your labor warranty cover?

- Do you pull permits and schedule inspections?

- Can you provide local references?

During visits, notice:

- Did they thoroughly inspect ductwork, insulation, and current equipment?

- Did they ask about your comfort priorities?

- Did they explain options without pressuring toward the most expensive choice?

Step 5: Compare Estimates Carefully

For each quote, document:

- Equipment brand, model, and capacity (tons)

- SEER2 efficiency rating

- Total price

- Equipment warranty length

- Labor warranty length

- Whether permits are included

- Financing terms, if applicable

Look beyond the bottom line:

- Is the equipment properly sized based on load calculations?

- Does efficiency qualify for available tax credits?

- What’s excluded that might add costs later?

Question significant price differences. If one quote is much lower, ask what’s being cut. If much higher, ask what’s being added.

Step 6: Arrange Financing

Before accepting contractor financing, compare:

- Personal loans from your bank, credit union, or online lenders

- Home equity products (lower rates, longer approval)

- FHA Title I loans (up to $25,000 for home improvements)

- 0% promotional credit cards (only if you’ll pay off before the rate increases)

- Contractor financing (convenient but often higher rates)

Get pre-approved before signing. Knowing your terms prevents pressure decisions.

Step 7: Finalize Your Decision

Before signing, confirm the contract includes:

- Specific equipment make, model, and capacity

- Total price with no “subject to change” language

- Start date and completion timeline

- Permit responsibility is assigned to the contractor

- Equipment and labor warranty terms

- Payment schedule

Protect yourself:

- Never pay more than 10-25% as a deposit

- Final payment due only after inspection approval

- Keep copies of all documents and warranties

Step 8: Prepare for Installation Day

Before the crew arrives:

- Clear pathways to equipment locations

- Remove items stored near the air handler or furnace

- Secure pets away from work areas

- Ensure someone 18+ is home throughout

Before the crew leaves, verify:

- System heats and cools properly

- All rooms receive adequate airflow

- The thermostat operates correctly

- You understand the filter replacement schedule

- You have warranty documentation

- Permit inspection is scheduled or completed

Step 9: Maintain Your Investment

Ongoing maintenance schedule:

- Monthly: Check and replace filters as needed

- Seasonally: Clear debris from the outdoor unit; check that vents are unobstructed

- Annually: Schedule professional maintenance before peak seasons

Keep records of:

- Installation date and contractor information

- Equipment model and serial numbers

- Warranty terms and expiration dates

- All service visits

Ready to Get Started?

Your immediate action items:

- Check rebates and tax credits at energystar.gov/rebate-finder

- Verify licensing requirements at nascla.org

- Request consultations from at least three licensed contractors

- Use this guide to evaluate recommendations and compare quotes

We’re here to answer questions, provide honest assessments, and deliver installations that perform as promised. When you’re ready, we’ll walk through your home’s specific needs and explain exactly what we recommend—and why.

Your comfort is worth getting this right.

FAQ on New HVAC System Cost for 2,000 Sq Ft House

Q: How much does a new HVAC system cost for a 2,000 square foot house in 2025?

A: Most homeowners pay $10,000 to $20,000, with the typical investment around $14,000 for complete heating and cooling.

Why the wide range? Every home presents different challenges:

- Under $10,000: Sound existing ductwork, straightforward replacement, standard efficiency equipment

- $12,000-$16,000: Typical installation with minor ductwork repairs, mid-range efficiency

- $18,000+: Ductwork replacement needed, high-efficiency equipment, complex access issues, or multi-zone systems

What we’ve learned: When someone quotes without walking through your home, they’re either planning surprises later or cutting corners you’ll pay for eventually.

Q: What size HVAC system do I need for a 2,000 square foot home?

A: The general range is 3 to 4 tons of cooling capacity and 60,000 to 100,000 BTUs of heating power. But square footage alone doesn’t determine the answer.

Factors that affect sizing:

- Ceiling height and home layout

- Window size, placement, and orientation

- Insulation quality and age

- Local climate conditions

- Tree coverage and sun exposure

What we see too often: Previous contractors eyeballed square footage and installed whatever they had on the truck. Those systems cycle constantly, never control humidity, and fail early.

The right approach: Manual J load calculation. It takes time but reveals what your specific home actually requires—not a guess based on general formulas.

Q: Is it worth paying more for a high-efficiency HVAC system?

A: It depends on how long you’ll stay in your home and your local energy costs.

The math on efficiency upgrades:

- Upgrading from 14 SEER2 to 20 SEER2 adds $2,000-$4,000 upfront

- Higher efficiency can reduce cooling costs by 30% or more annually

- Typical payback period: 5-7 years in hot climates

Tax credits change the equation:

- Central air conditioners: up to $600

- Heat pumps: up to $2,000

- These incentives significantly shorten payback periods

When high-efficiency makes sense:

- You plan to stay 5+ years

- You run your system heavily

- You want to maximize available tax credits

When mid-range efficiency makes sense:

- Selling within 3 years

- Vacation or rental property

- Budget constraints outweigh long-term savings

Our approach: We’ve talked homeowners out of premium equipment when it didn’t serve their situation. No commission is worth recommending the wrong solution.

Q: How can I tell if an HVAC contractor is trustworthy?

A: After years of fixing other contractors’ mistakes, we’ve identified clear patterns.

Signs of a trustworthy contractor:

- Provides the license number without hesitation

- Welcomes verification through the state licensing board

- Performs Manual J load calculations

- Pulls permits and schedules inspections

- Explains recommendations in plain language

- Answers questions without pressure tactics

- Puts all details in writing

Red flags to avoid:

- Quotes dramatically lower than competitors without explanation

- Pressure to decide immediately

- Reluctance to provide written specifics

- Cash-only requests

- Sizing based on square footage alone

- Resistance to discussing credentials

Our recommendation: Check BBB complaint history. A contractor’s website shows curated reviews. The BBB shows how they handle problems—and that reveals everything.

Q: Should I repair my current HVAC system or replace it entirely?

A: Some contractors always recommend replacement. Here’s our honest framework.

Repair makes sense when:

- The system is under 10 years old

- Repair costs less than 50% of replacement

- No pattern of recurring breakdowns

- Equipment still uses current refrigerants

Common repairs worth doing:

- Capacitor replacement: $150-$300

- Blower motor: $400-$600

- Refrigerant recharge: $200-$500

- Contactor replacement: $150-$300

Replacement makes sense when:

- System exceeds 15 years old

- Uses R-22 refrigerant (phased out, expensive)

- Repairs exceed 50% of replacement cost

- Consistent comfort problems despite service

- Energy bills are rising without explanation

What we’ve seen: Sometimes a 12-year-old system technically runs but operates so inefficiently that replacement pays for itself through monthly savings.

Our commitment: We give the same advice we’d give family—even when that means recommending repair instead of making a sale.

Ready to Get an Accurate HVAC Estimate for Your 2,000 Sq Ft Home?

Stop guessing about costs and start with a proper assessment. Contact Filterbuy HVAC Solutions today for a free in-home consultation that includes Manual J load calculations, honest recommendations, and transparent pricing—no surprises, no pressure.